Aliphatic polyamides na sassa daban-daban an samar da su ta hanyar kasuwanci, wanda PA6, PA66, PA46, PA11 da PA12 sune mafi mahimmanci.Lalacewar Oxidative a cikin PA ya dogara da matakin crystallinity da yawa na lokacin amorphous.Bisa ga hanyar gargajiya, an daidaita polyamides aliphatic tare da ƙananan gishiri na jan karfe (har zuwa 50 ppm) tare da halogen ions (irin su aidin da bromide ions).Ingancin wannan tsarin stabilizer yana da ban mamaki saboda ions jan ƙarfe ana ɗaukar taimakon tsufa a cikin polyolefins.Har yanzu ana nazarin tsarin daidaita tasirin jan ƙarfe/halogen.

Amine amines sune masu daidaitawa na yau da kullun waɗanda ke haɓaka LTTS, amma idan aka yi amfani da su a PA, suna iya haifar da canza launin polymers.Phenol antioxidants na iya inganta launi na farko bayan polycondensation don daidaita polyamide aliphatic.Gabaɗaya, ana ƙara wannan maganin antioxidant kafin a daina ɗaukar ƙwayar cuta.

Teburin da ke ƙasa yana kwatanta kaddarorin na'urori daban-daban waɗanda aka yi amfani da su don polyamide aliphatic.

| tsarin AO | Amfani | Rauni |

| Gishiri na jan karfe / iodide | Mai tasiri sosai a ƙananan ƙira Lokacin da yawan zafin jiki ya wuce 150 ° C, yana ba da gudummawa sosai ga LTTS na polymer | Rashin rarrabawa a cikin polymers Leaching yana faruwa cikin sauƙi lokacin da ake hulɗa da ruwa ko ruwa / abubuwan kauri Zai iya haifar da canza launi |

| Amines na kamshi | Yana ba da gudummawa sosai ga LTTS na polymers | Kasance cikin babban taro canza launi |

| Phenols | Yana ba da gudummawa sosai ga LTTS na polymers Kyakkyawan aikin launi Za'a iya ƙarawa yayin aiwatar da maida hankali Babu halayen gefe da ke faruwa tare da sauran polymers yayin haɗuwa |

A yanayin zafi mai girma (misali sama da 150 ° C), tsarin ƙarfafa tagulla/iodide yana nuna kyakkyawan sakamako.Duk da haka, a ƙananan yanayin zafi, phenolic antioxidants kadai ko a hade tare da phosphites na iya zama mafi tasiri.Wani fa'idar yin amfani da antioxidants phenolic shine cewa suna riƙe babban launi na polypolymers har sai zafin tsufa ya fi inganci fiye da masu daidaita gishirin jan karfe.

A discoloration na polymer bayan zafi tsufa ba ya rage a layi daya tare da inji Properties.Rarraba launi na iya faruwa ko da a cikin ɗan gajeren lokaci, amma ƙarfin ƙwanƙwasa ƙarfi da haɓakar polymer ba za a yi tasiri ba har sai daga baya.

Babban jigon wallafe-wallafen yana kwatanta aikace-aikacen da yawa na gilashin-fiber ƙarfafa polyamides a cikin masana'antar kera motoci, irin su ruwan injin injin, iyakoki da grilles, birki da masu tara wutar lantarki, hannayen bawul, tayoyi, masu tuntuɓar birki na iska da hoods.Phenolic antioxidants, ko dai shi kadai ko a hade tare da phosphite, sune mafi kyawun masu daidaitawa don GFR PA66.

Tushen tsarin haɗin phenol + phosphite shine 1098+168, wanda za'a iya amfani dashi zuwa yanayin yanayin aiki mara ƙarancin inganci, kuma an inganta launi na extrusion.Duk da haka, don tsarin polyamide kamar ƙarfin ƙarfin fiber gilashi, zafin aiki ya fi girma (kusan 300 ° C), gazawar bazuwar zafin jiki na 168, a wannan lokacin, galibi muna amfani da 1098 + S9228 irin wannan haɗuwa da mafi kyawun juriya na zafin jiki, wanda kuma shine mafi girman juriya. dabarar da aka fi amfani da ita a cikin nailan mai zafin jiki.

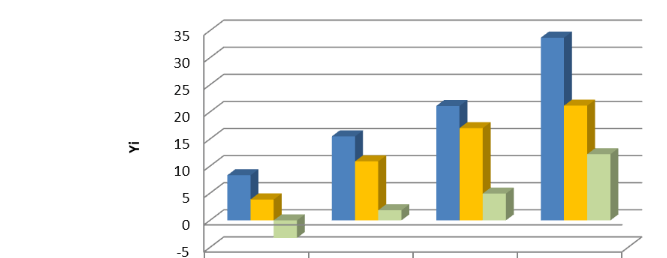

Bayan sakamakon gwaji na tsari, an gano cewa 1098 + S9228 har yanzu yana da damar ingantawa a cikin ingantaccen launi na nailan mai zafi mai zafi, kuma Sarex Chemical ya ƙaddamar da samfurori da aka inganta SARAFOS 2628P5 (juriya na tushen phosphorus) da SARANOX PA2624 (wanda ke hana phenol da phosphite). hade) suna da mafi kyawun aiki a cikin rawaya mai zafi mai zafi na nailan, kuma bayanan gwajin da suka dace sune kamar haka:

PA66, 270°C extrusion da yawa da gwajin yin burodi

| ■0.1%1098+0.2%9228 | 8.32 | 15.5 | 21.11 | 33.71 |

| ■0.1%109810.2%2628P5 | 3.85 | 10.88 | 17.02 | 21.16 |

| ■3% PA2624 | -3.25 | 1.87 | 4.94 | 12.21 |

Abubuwan da ke sama an ƙaddara su ta hanyar dakin gwaje-gwajen Chemical Sarex

Idan aka kwatanta da adadin adadin SARAFOS 2628P5 da S9228, launi na extrusion da yawa da kuma ajiyar zafi na 120 ° C don 12h suna da kyakkyawan aiki, kuma juriya na hydrolysis na samfurin kanta yana da kyau fiye da na S9228, wanda ke da aikace-aikace mai kyau. abubuwan da ke faruwa a cikin canjin PA.

Lokacin da akwai buƙatu mafi girma don launi na farko, ana bada shawara don ƙara SARANOX PA2624, ban da foda foda, za mu iya ba abokan ciniki tare da PA antioxidant masterbatches da kwayoyin antioxidant masu ɗaukar kaya, wanda ya dace don ƙarawa da watsawa, da taimako. taron samarwa ya zama mara ƙura.

| PA66, extrusion da yawa a 270 ° C | 0.1% 1098 + 0.2% 9228 | 0.1% 1098+0.2%2628P5 | 0.3% PA2624 |

| 1 extrusion |  |  |  |

| 3 extrusion |  |  |  |

| 5 extrusions |  |  |  |

| Gasa a 120 ° C, awa 12

|  |  |  |

Abubuwan da ke sama an ƙaddara su ta hanyar dakin gwaje-gwajen Chemical Sarex

Lokacin aikawa: Nuwamba-14-2022